Paints & Coatings

Coatings and paints are ubiquitous in our everyday lives for decorative and aesthetic purposes, but also to protect and isolate the covered surfaces and materials from their environments. For example, metallic surfaces would oxidate very quickly without any suitable protection from corrosion. These functional layers can add new functionalities to the substrate too. From our modern smartphones’ screens covered by anti-fingerprint top-layer coatings to avoid unsightly traces on their surfaces to self-healing varnishes applied on polymeric matrices to reduce cracks: coatings are employed in diverse domains.

Wettability

Paints and coatings are formulated to meet specific requirements in terms of properties. Their application on various materials is dependent from a suitable wettability on these substrates. For that purpose, our functional molecules can be used as additives or precursors to tailor the surface energy of the blend and provide good wetting of the surface to apply a homogeneous layer.

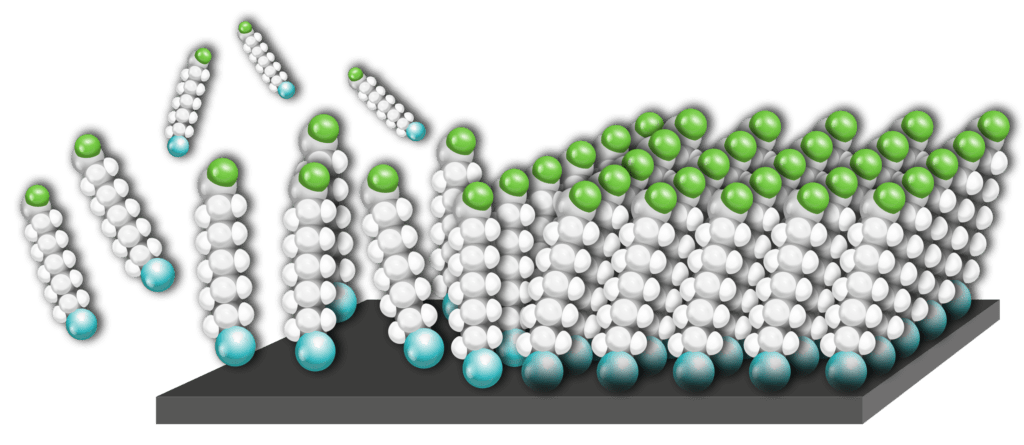

Adhesion Promotion

Moreover, to ensure their protective and functional roles, coatings need to present a good adhesion on the covered parts. For that reason, adhesion promoters can be applied preliminary on the surface. Our bi-functional molecules can play this role by creating chemical bonding at the interface: one functional group will react with the substrate and the second chemical group with the matrix of the coating to provide covalent linkage, which will ensure a long-lasting attachment of the layer on the material.

Dispersibility and Stability

In coating development, selecting the right fillers and precursors is pivotal for achieving the targeted color, finish, and mechanical robustness, while ensuring the formulation possesses optimal flow properties. Proper dispersibility and stability are key to circumventing problems such as flocculation, demixing, or phase separation, which can compromise the uniformity and performance of the coating. Minimizing these issues reduces the need for intensive shearing processes, promoting a smooth application and a consistent final layer, essential for maintaining the coating’s aesthetic and functional integrity.

Green Coatings

The market of Green Coatings is constantly growing and projected to reach near 156 billion dollars by 2027. This trend includes waterborne, powder and high solid content coatings to limit the use of harmful solvents.

We are actively involved in the European project BIO-SUSHY, aimed at identifying sustainable alternatives to PFAS by utilizing green coatings. This project underscores our commitment to fostering innovative and environmentally friendly solutions within the coatings industry.

SiKÉMIA can supply various linkers, which are suitable for these types of greener products. Moreover, a new range of biobased compounds is under development. Please visit our shop.