Adhesion Promotion for High Performance Surface Treatments

In the intricate world of materials science and manufacturing, the strength and durability of bonds between different substances have long been paramount. As industries continue to push the boundaries of what materials can achieve, two exciting frontiers have emerged in the realm of adhesion promotion: advanced materials and nanocoating.

Advanced materials

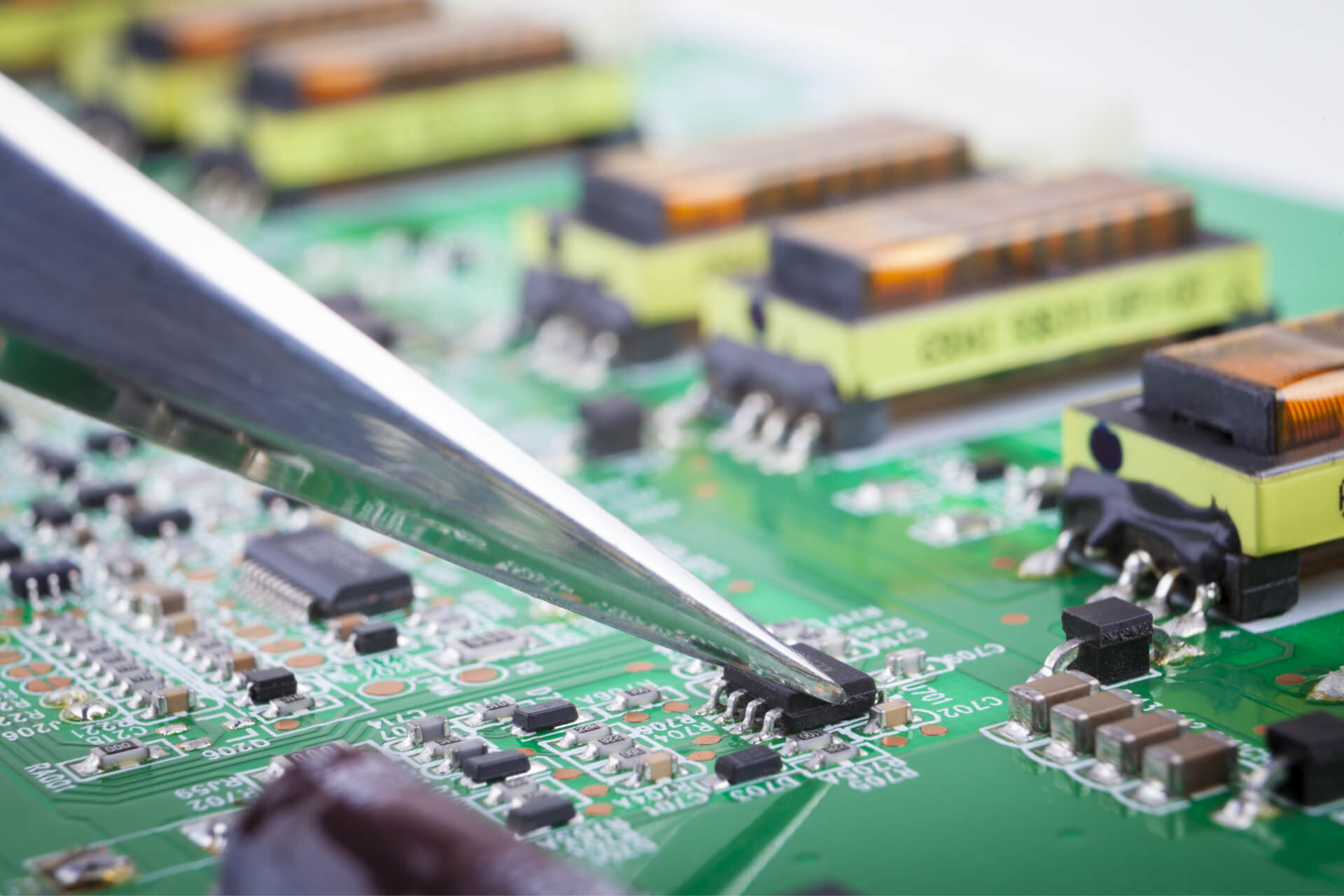

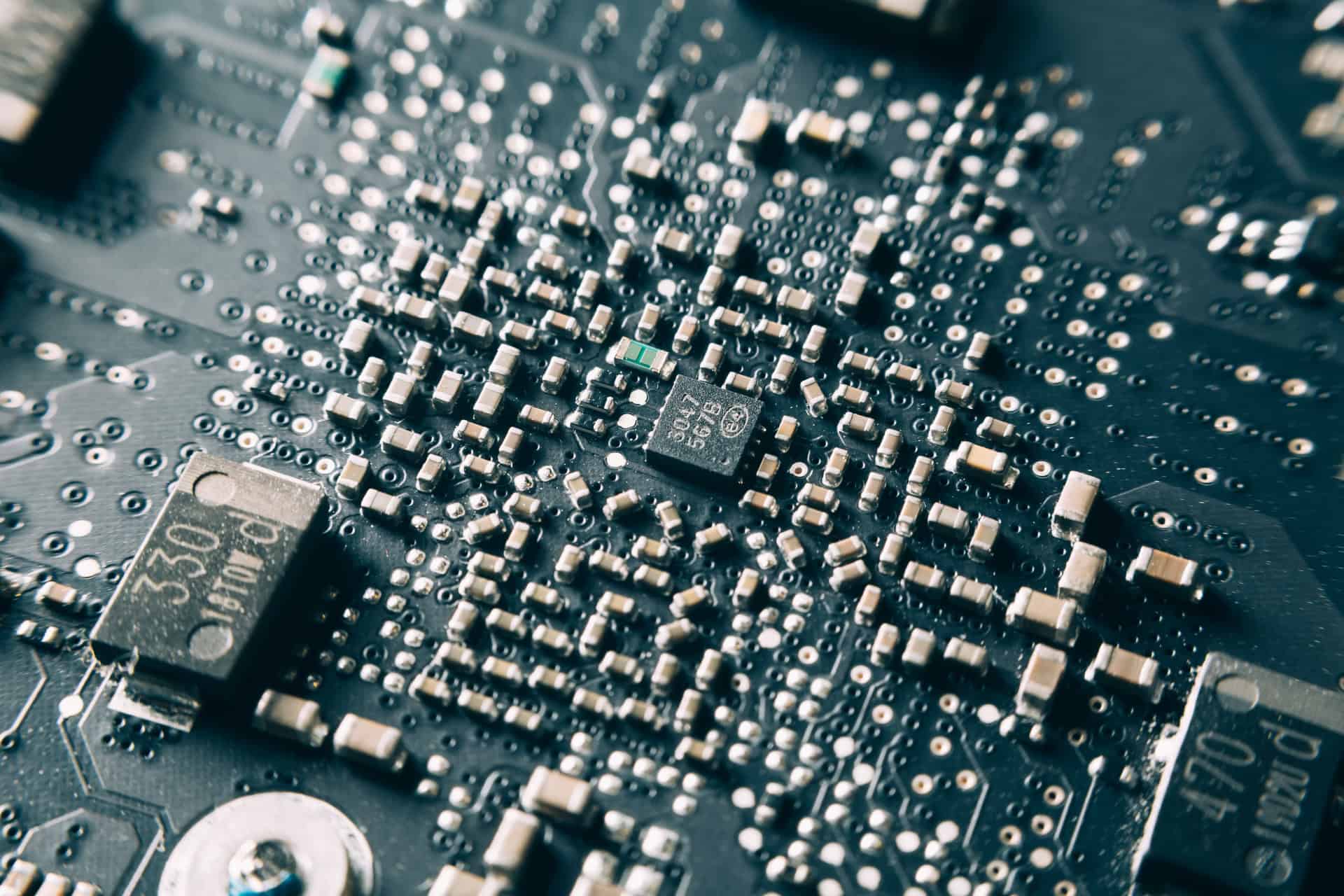

Advanced materials offer a wide range of benefits over traditional materials, such as improved performance, durability, and sustainability. However, one of the challenges associated with using advanced materials is that they can be difficult to bond to other materials. This is due to their unique surface properties, which can make them incompatible with traditional adhesives. Adhesion promotion linkers (APLs) are a class of surface modifiers that can be used to improve the adhesion of two materials. APLs work by creating a chemical bridge between the two surfaces, which helps to distribute stress and improve wetting. This results in a stronger and more durable covalent bond. Overall, APLs are a valuable tool for improving the performance, durability, and safety of a wide range of products. By improving the adhesion of materials, SiKÉMIA’s APLs can help to reduce costs, improve safety, and extend the life of products.

Nanocoating

SiKÉMIA’s liquid functionalization process is a cutting-edge technique for surface modification, offering exceptional versatility and effectiveness in a wide array of applications. This process relies on self-assembled monolayers (SAMs) as linkers, forming covalent bonds between coatings and substrates to create robust and enduring connections while maintaining material transparency and appearance. One of its key strengths lies in its simplicity. Linkers are dissolved in a liquid and then applied to the surface, where they self-assemble and establish a chemical bond with the substrate. This ease of use is complemented by scalability, making it suitable for industrial applications, as it can swiftly cover large surfaces. SiKÉMIA’s liquid functionalization isn’t limited to specific materials; it can be effectively employed on metals, plastics, glasses, ceramics, and more. Furthermore, it allows for the creation of various coatings, including hydrophobic, hydrophilic, and anti-reflective, tailored to meet specific industry requirements.

Linked Markets

Life Sciences

Chemical surface modification is widely used in the life sciences industry to develop advanced biomaterials, drug delivery systems, and diagnostic tools.

Learn more

Paints & Coatings

Coatings and paints are omnipresent in our daily lives, from decoration and aesthetics to the protection and insulation of surfaces and materials.

Learn more

Luxury Industry

The surface chemistry is a technology that consists of modifying the properties of material surfaces at the nanoscale.

Learn more

Automotive

The automotive industry demands innovation, high accuracy, and quality, all of which are SiKEMIA strengths.

Learn more

Aerospace

Our extensive range of coatings, and ligands, we meet all the requirements set by the aerospace industry.

Learn more