Non-Stick Coating

Anti-adhesive properties are essential in enhancing product efficiency and longevity across various sectors. They reduce surface friction and wear, leading to improved energy efficiency and component durability. These properties are crucial for easier cleaning and maintenance, minimizing contamination risks. In precision environments like electronics, they protect against dust and moisture, ensuring optimal functionality. The use of advanced materials, particularly hydrophobic nanocoatings, represents a significant technological advancement, providing innovative solutions to diverse industrial challenges.

Maritime and Shipping

In maritime and shipping, anti-adhesive coatings are essential for preventing marine organisms from attaching to hulls and underwater structures. This biofouling prevention reduces drag, significantly cutting fuel consumption and operational costs. It also lessens the environmental impact by reducing emissions and the use of harmful cleaning chemicals, making it a sustainable choice for the industry.

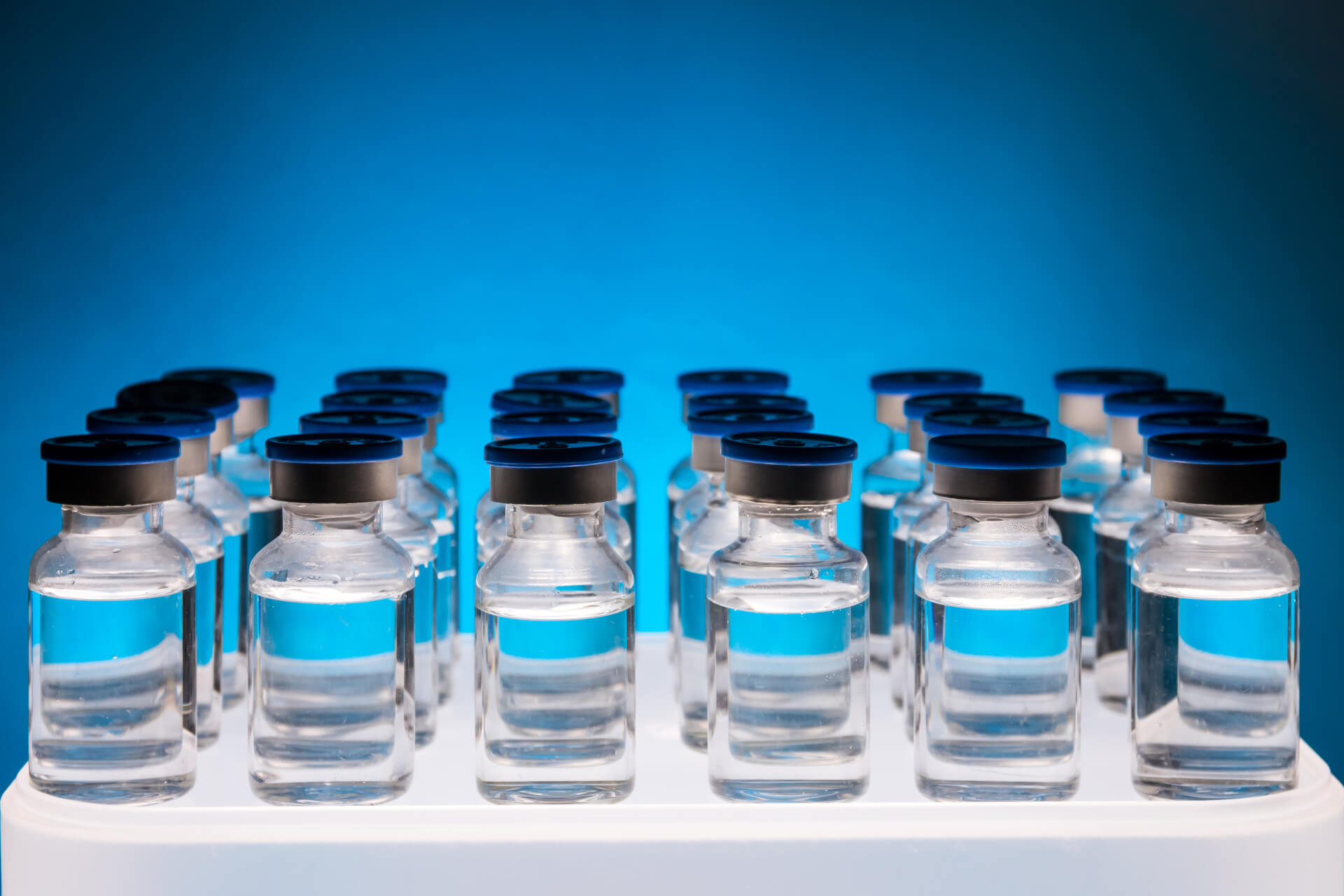

Medical and Healthcare

The medical and healthcare industry greatly benefits from non-stick technologies. They prevent tissue adhesion during surgeries, reducing complications and recovery times. In medical devices and implants, these properties inhibit bacterial colonization, lowering infection risks. This advancement is crucial for patient safety and the effectiveness of medical treatments and prosthetics.

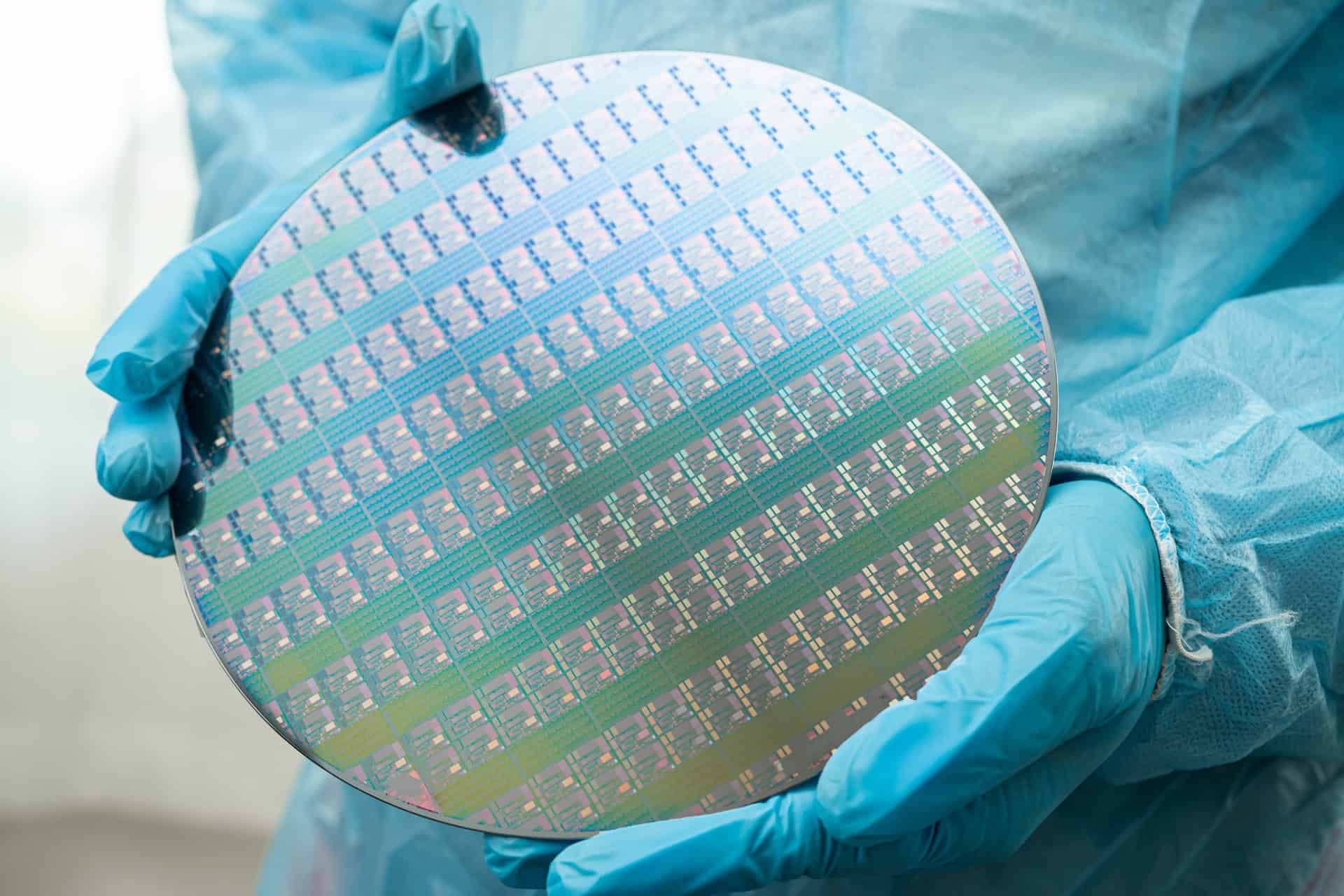

Electronics and Optoelectronics

Anti-adhesive properties in electronics and optoelectronics protect sensitive components from dust and moisture accumulation, crucial for maintaining functionality and prolonging device life. This is particularly important in high-precision environments where even minor contaminants can disrupt performance, ensuring reliability and efficiency in increasingly miniaturized and complex systems.

Automotive and Aerospace

In the automotive and aerospace industries, non-stick coatings are applied to reduce friction and wear on parts. This leads to enhanced fuel efficiency and extended lifespan of components. The technology also plays a role in reducing maintenance needs and costs, contributing to the overall safety and performance of vehicles and aircraft.

Food Processing and Packaging

Anti-adhesive technologies in food processing and packaging ensure easy cleaning of equipment, maintaining hygiene standards and preventing contamination. This reduces product wastage during packaging and transfer, leading to cost savings and improved efficiency. It’s a critical factor in maintaining food quality and safety throughout the supply chain.

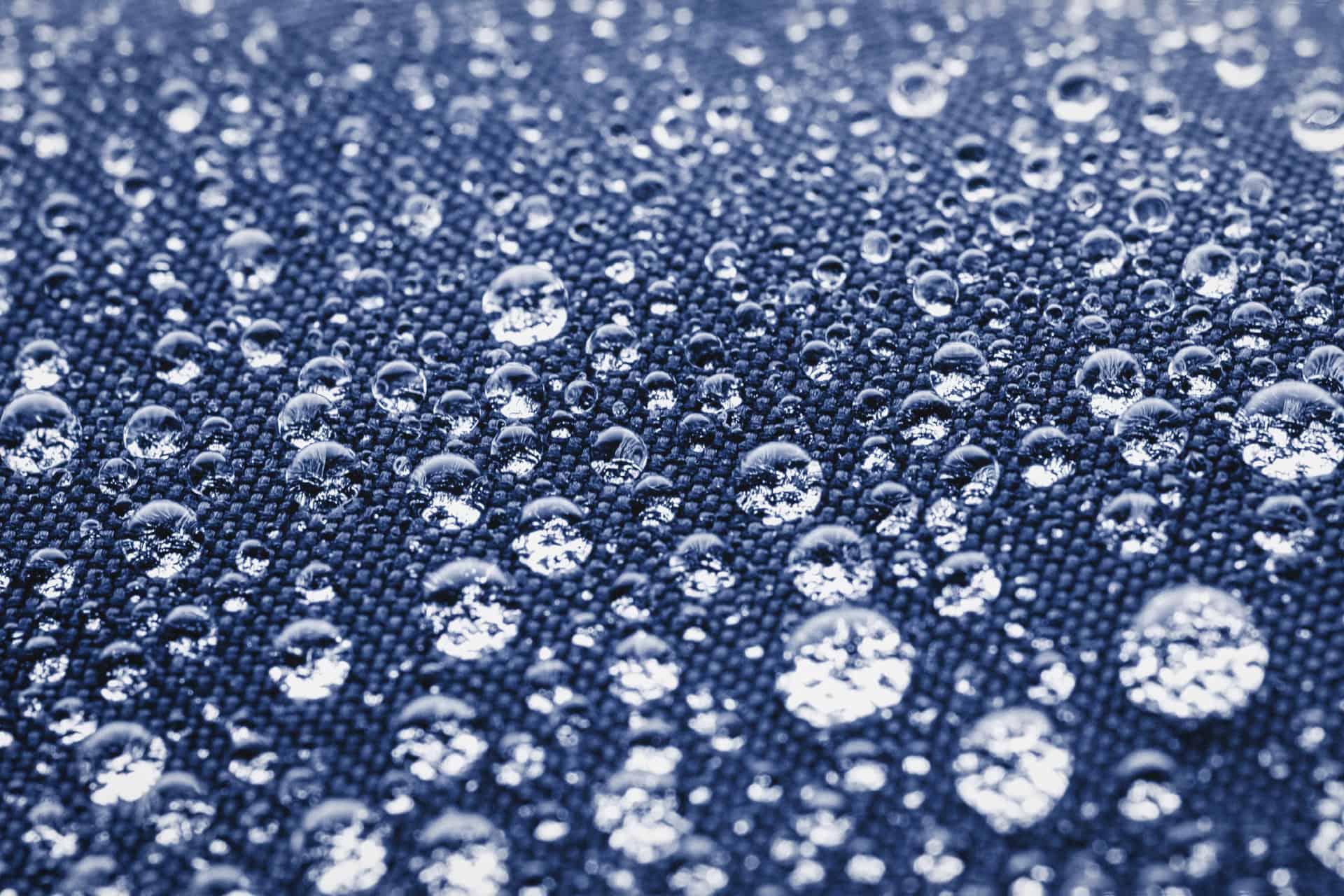

Textile Industry

The textile industry employs non-stick treatments to create stain-resistant and easy-to-clean fabrics. This not only extends the life and appearance of garments and textiles but also reduces the need for frequent washing, contributing to environmental sustainability by saving water and reducing detergent use.

Construction and Building

In construction, anti-adhesive paints and coatings are used to keep buildings and structures clean. They prevent dirt, graffiti, and other substances from adhering, simplifying maintenance and preserving aesthetic appeal. This technology is especially beneficial in urban areas, where buildings are more prone to such exposure.

Watchmaking and Precision Instruments

The watchmaking and precision instruments sector relies on non-stick coatings to control the spread of lubricants within mechanisms. This precision ensures that the mechanisms function smoothly over long periods, maintaining accuracy and reliability, which is paramount in high-quality timepieces and intricate instruments.

Linked Markets

Life Sciences

Chemical surface modification is widely used in the life sciences industry to develop advanced biomaterials, drug delivery systems, and diagnostic tools.

Learn more

Paints & Coatings

Coatings and paints are omnipresent in our daily lives, from decoration and aesthetics to the protection and insulation of surfaces and materials.

Learn more

Luxury Industry

The surface chemistry is a technology that consists of modifying the properties of material surfaces at the nanoscale.

Learn more

Automotive

The automotive industry demands innovation, high accuracy, and quality, all of which are SiKEMIA strengths.

Learn more

Aerospace

Our extensive range of coatings, and ligands, we meet all the requirements set by the aerospace industry.

Learn more