Grafting Function : chemical group specifically chosen to react with the target surface, forming a strong covalent bond for robust attachment.

Advanced Surface Engineering

Drawing on advanced surface engineering techniques and extensive expertise developed through years of research, SiKÉMIA delivers specialized R&D outsourcing services through tailored surface modification solutions. Designed for the most challenging industrial applications, our approach helps break technological locks and guarantees reliable, high-performance results. By blending innovative methods with practical industry needs, we consistently deliver outcomes that meet our clients’ expectations.

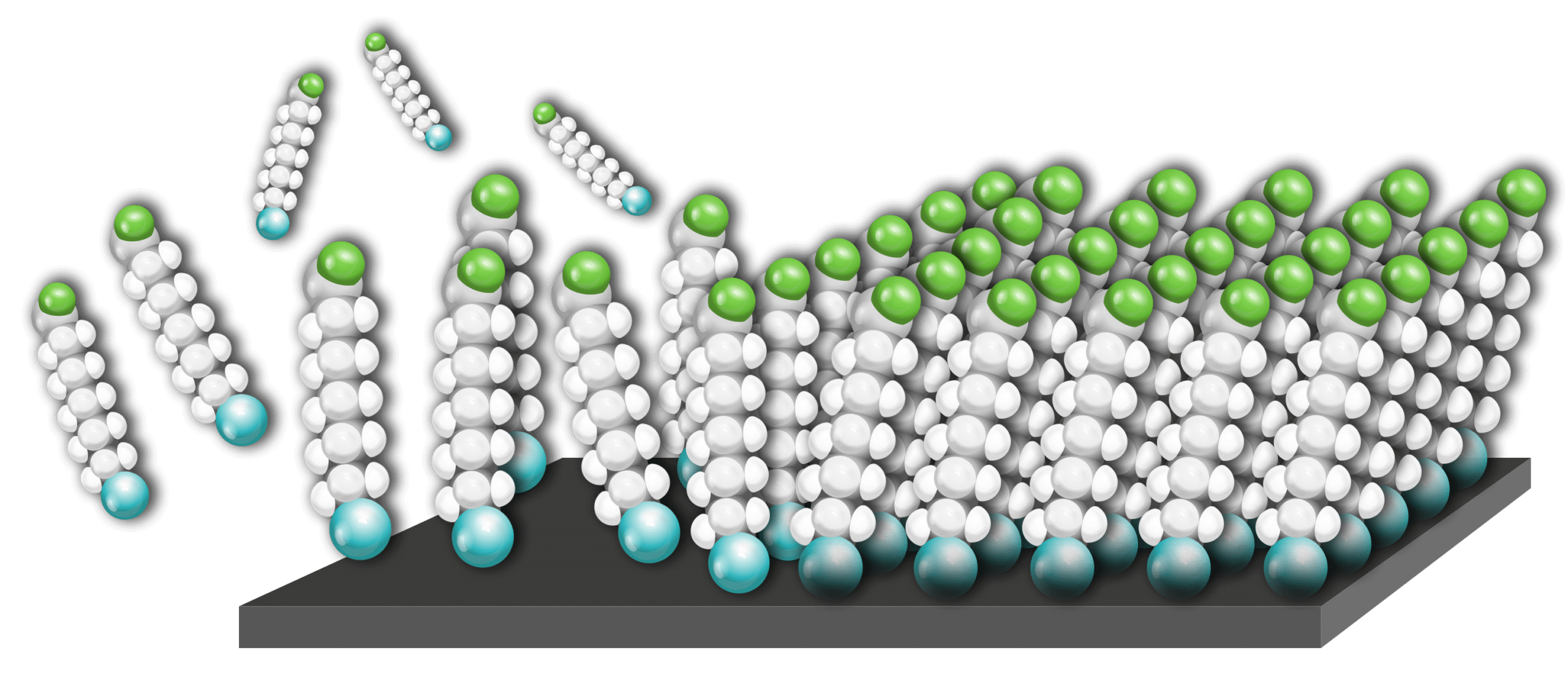

SAMs

Surface engineering using self-assembled monolayers (SAMs) allows for the development of transparent, flexible, and easily applied nanocoatings. This technique enhances the properties of various materials, including metals, metal oxides, semiconductors, glass, and ceramics, even on complex surfaces like flat substrates, nanostructured surfaces, or powders.

SAMs are organic structures formed by the adsorption of specific molecules (in solution or gas phase) onto a substrate, where they spontaneously arrange into an ordered monolayer. By utilizing this technology, industries can improve durability, adhesion, and specialized functionality for applications in electronics, biomedical devices, coatings, and beyond.

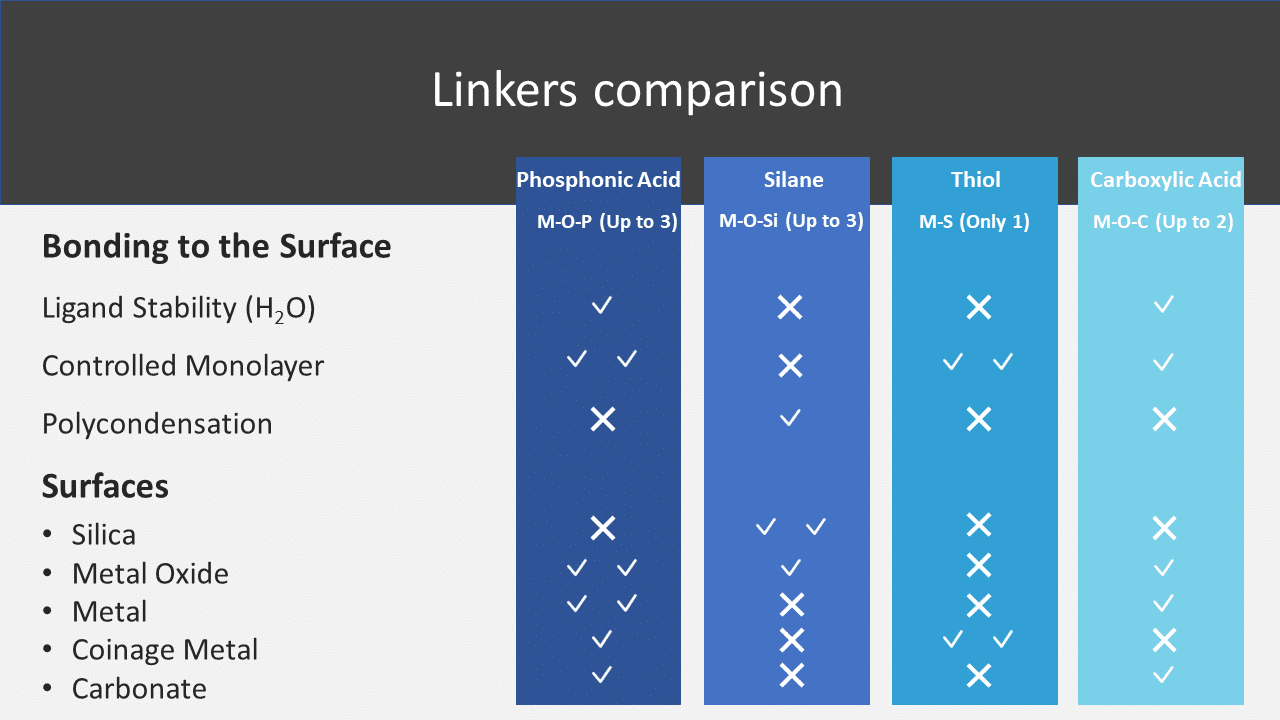

Linkers

Self-assembled monolayers (SAMs) typically consist of bifunctional linkers with three key parts:

At SiKÉMIA, our catalog includes over 400 specialized linkers, covering silicon, phosphorus, sulfur, and carbon chemistries. Using this advanced surface modification technique, you can:

This versatile surface engineering platform enables manufacturers and researchers to customize material properties with remarkable precision, breaking the way for advanced nanocoatings across various industries.

Our Surface Modification Process Service

1. Feasability Study & specifications

Evaluation of material properties and project viability to understand potential challenges and opportunities.

2. Choice of the most suitable linker

Selection of the appropriate linker molecules based on surface type, desired properties, and application needs.

3. Grafting Step

Attachment of the linker to the surface using advanced techniques, ensuring uniform modification and stability.

4. Process Optimization

Enhancement performance and longevity of the modified surface through careful adjustment of modification conditions and rigorous testing.

5. Technology Transfer

Provision of comprehensive support and information to enable the client to independently implement the surface modification process in their own facilities.

1. Consultation and Quotation

Engage with the customer to understand their needs and provide a detailed quotation for the custom solution required.

2. Material Selection and Compliance

Select the appropriate chemical compounds and solvents, ensuring they meet safety standards and regulatory compliance.

3. Solution Preparation

Mix and dissolve the chemical compounds in the chosen solvent to the specified concentration in a controlled environment.

4. Quality Control and Certification

Perform quality checks to confirm the solution meets the required specifications and issue a Certificate of Analysis.

5. Packaging and Documentation

Package the solution in appropriate bottles with proper labeling and prepare all necessary documentation for traceability and safety.

6. Delivery and Customer Support

Deliver the custom solution to the customer and provide support for any further information or assistance required.

Contact Us

"*" indicates required fields